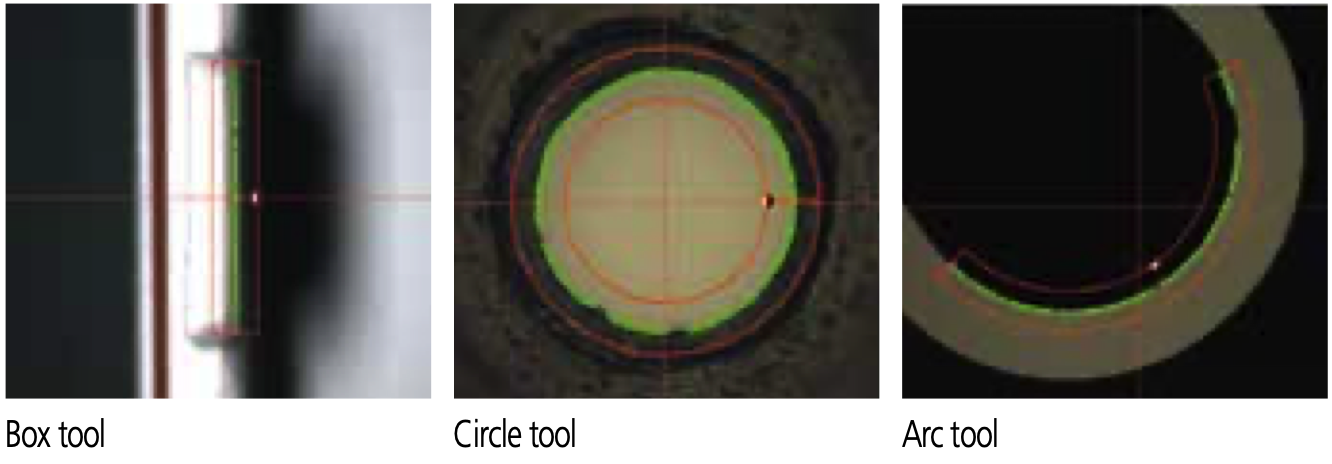

Helps control the inhomogeneity of measurement data.

- Automatic edge detection with “Automatic edge detection” function ensures repeatable measurements with high accuracy. Reduce errors from different measurement skills of the operator

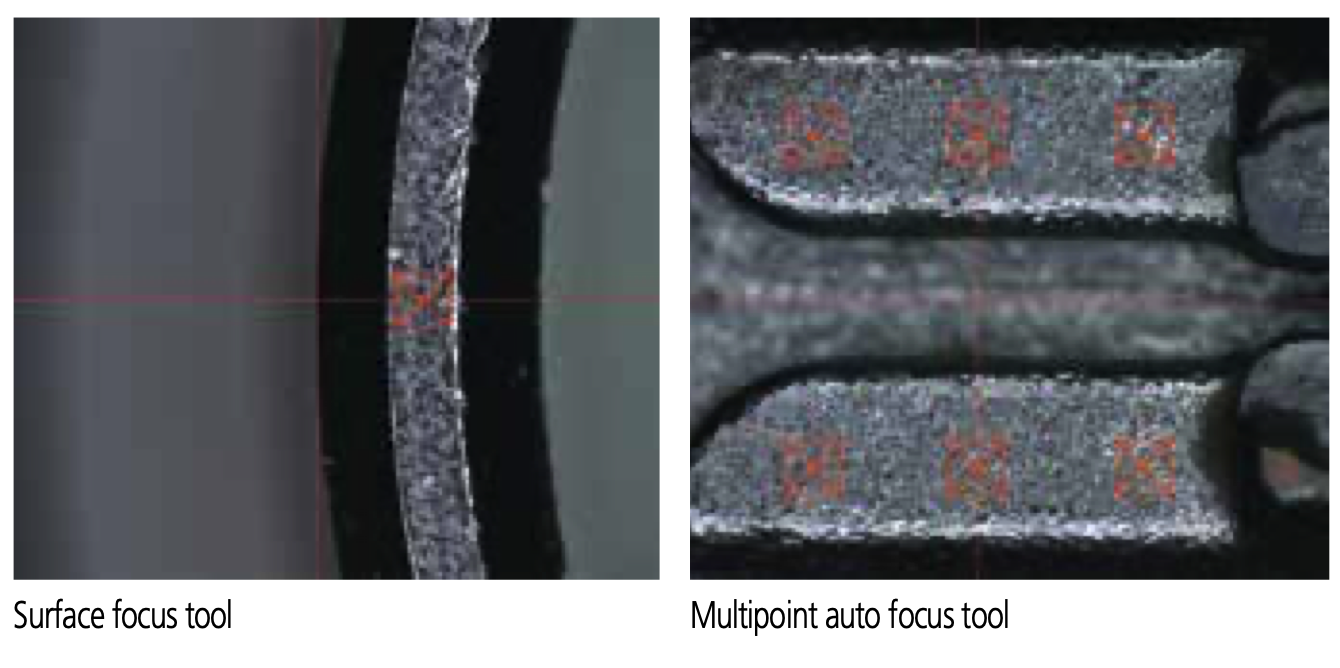

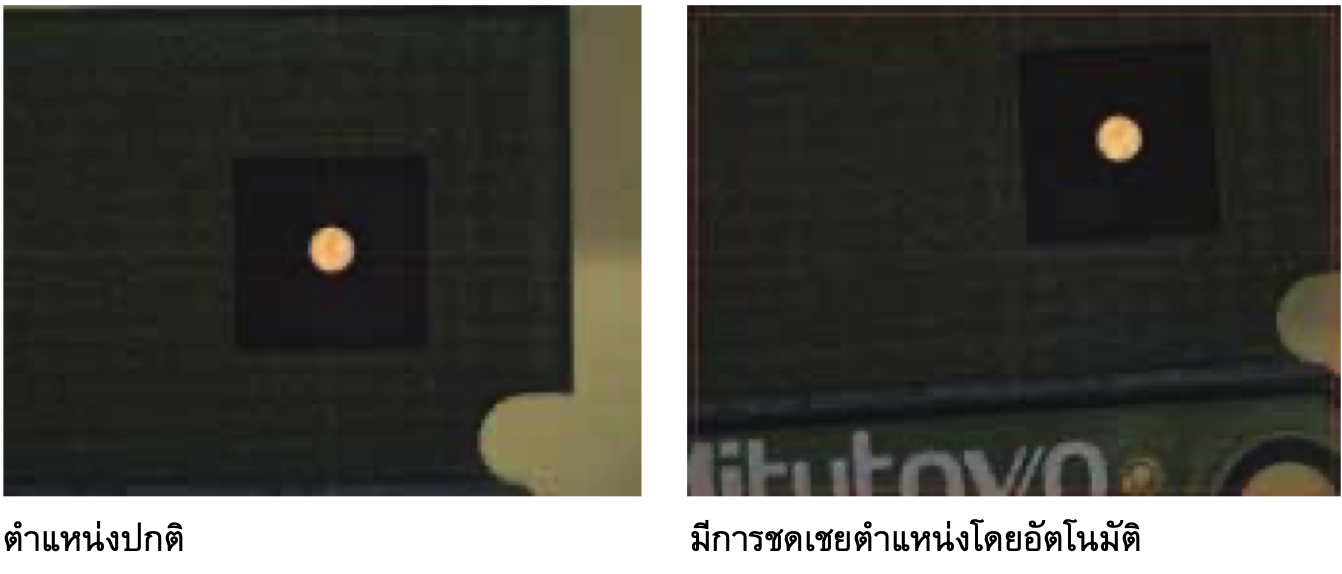

Image auto focus

- Proper setting of the “Image auto focus” function enables fast depth-of-field measurement and reliable results.

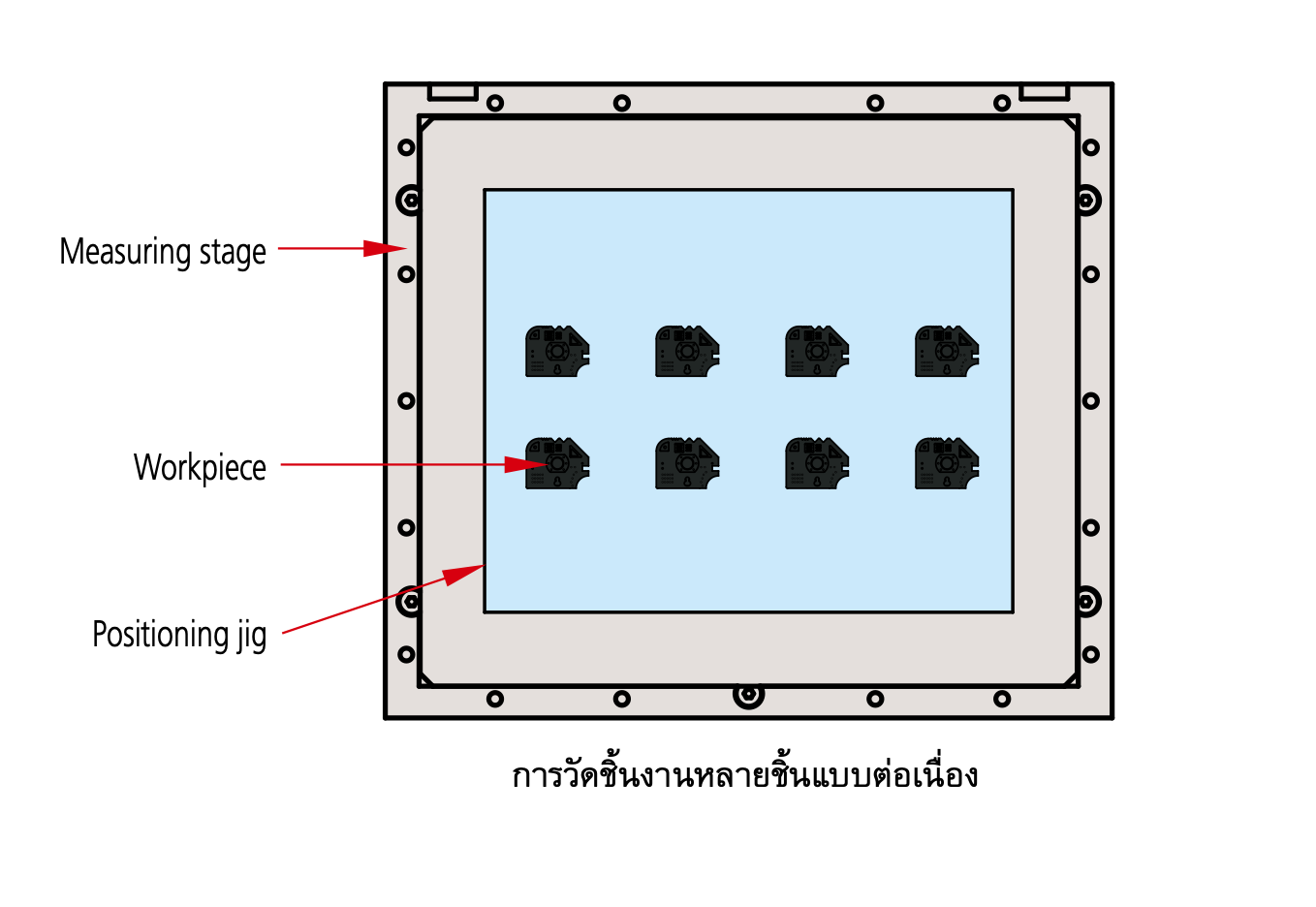

Continuous measurement of large numbers of workpieces Step & repeat

- The “Step & repeat” function allows measurement of a large number of workpieces on the positioning jig from a single Part Program run.

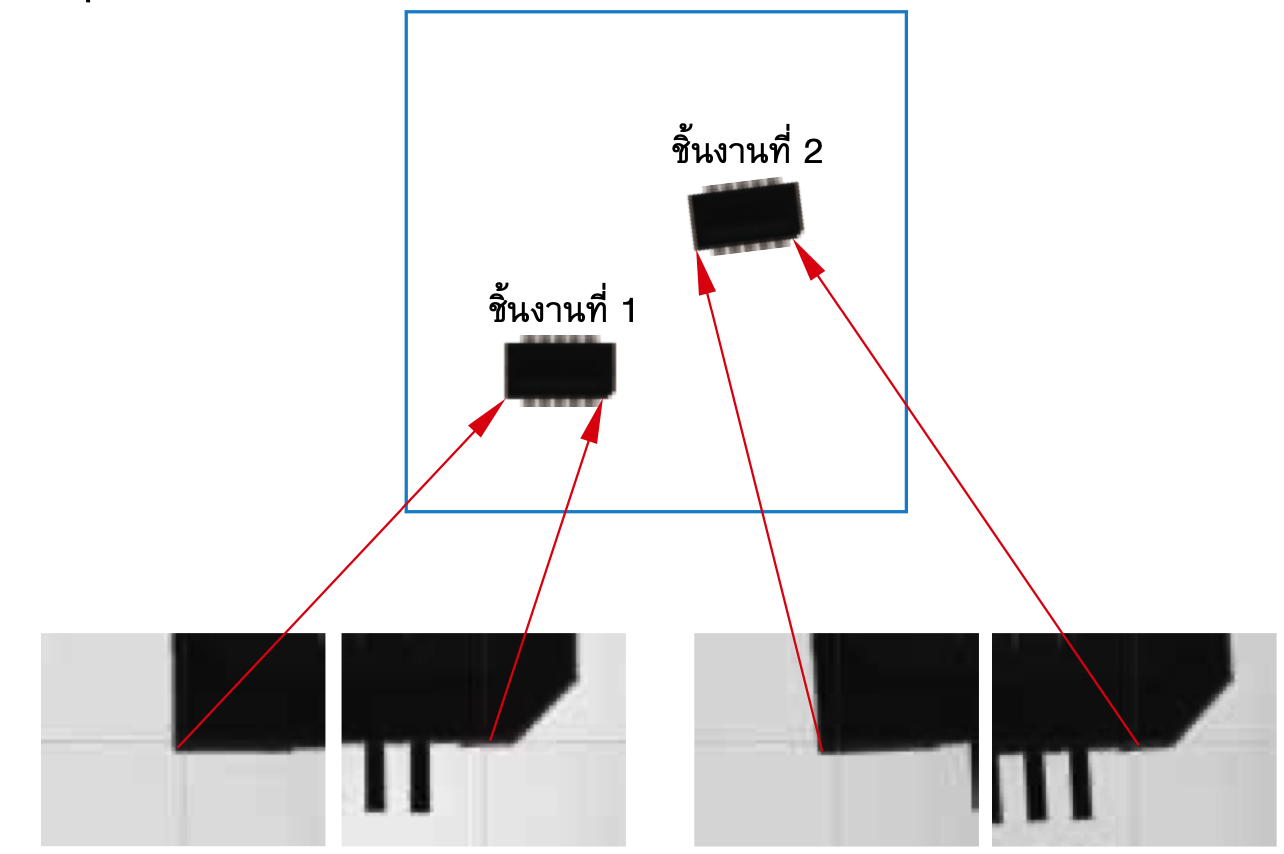

Automatic measurement can be started immediately by specifying a rough position. Pattern search

- The “Pattern search” function can automatically detect shapes based on the shape of the workpiece recorded in the system.

Manual tool

- Combining “Manual Tool” measurement with automatic measurement allows measurement with temporary positioning. It is possible to start automatic measurement on the workpiece table from any position without using a positioning jig. This makes it possible to reduce costs and working hours. Ability to measure three-dimensional workpieces continuously

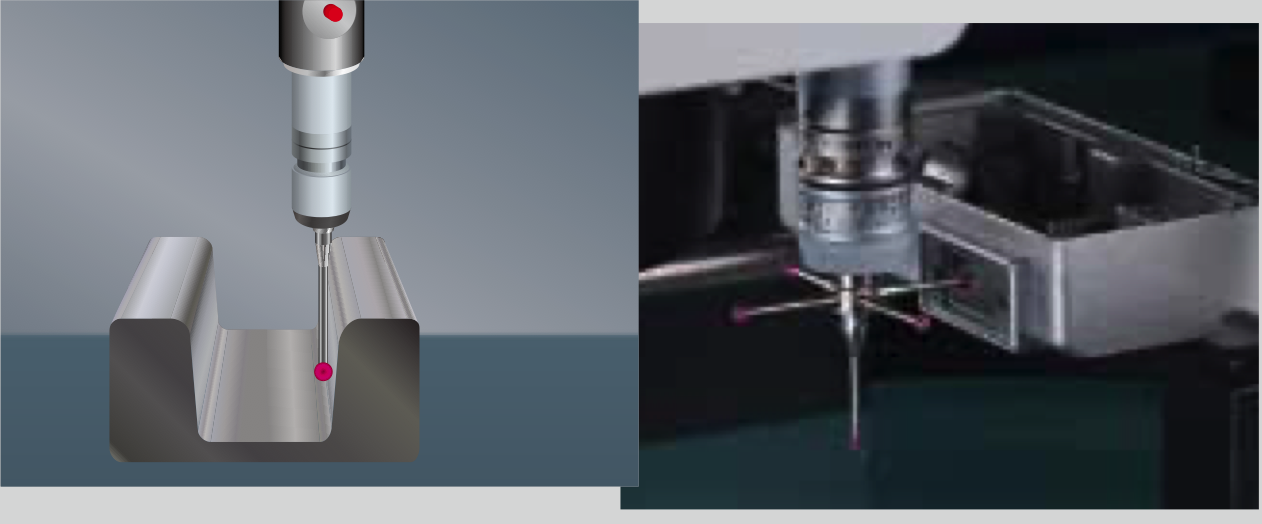

The model has a touch probe head.

- For vision measurement systems Measuring the side surfaces of three-dimensional objects or measuring the height of a metal/resin mold This can be done using a contact probe (probe).