The manufacturer’s technology is rapidly adaptable and better, under the concept: The A Brand, convenient and easy to choose and use.

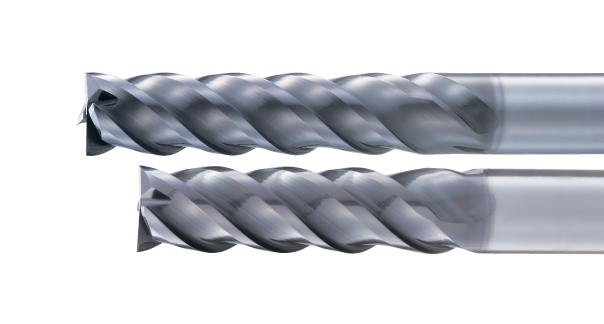

- AE-VM Series Vibration-proof carbide end mills are suitable for a wide range of materials, from carbon steel, alloy steel, stainless steel or stainless steel to titanium alloys and Ni-based alloys.

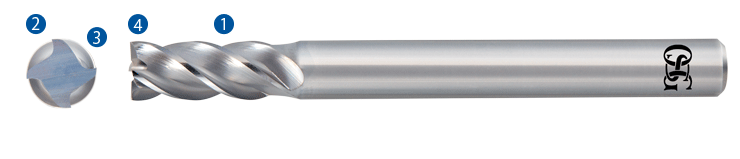

Features

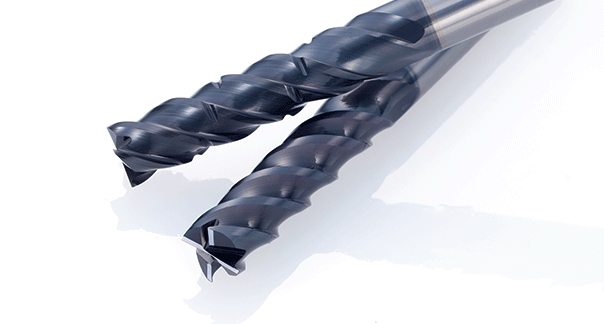

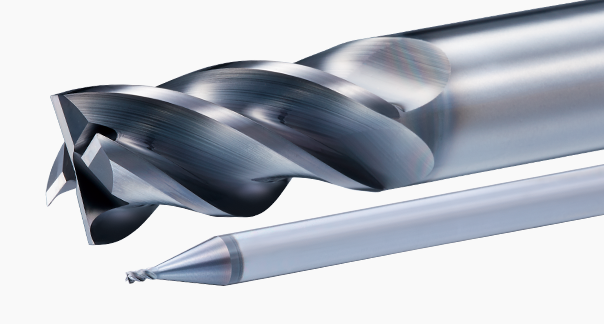

Anti-Vibration Short Carbide End Mill

- “DUARISE coating” provides excellent lubricity, superior friction-resistance and high oxidation temperature

- Sharp positive rake angle reduces cutting force

- New flute form enables excellent chip evacuation

- Variable-lead geometry suppresses vibration

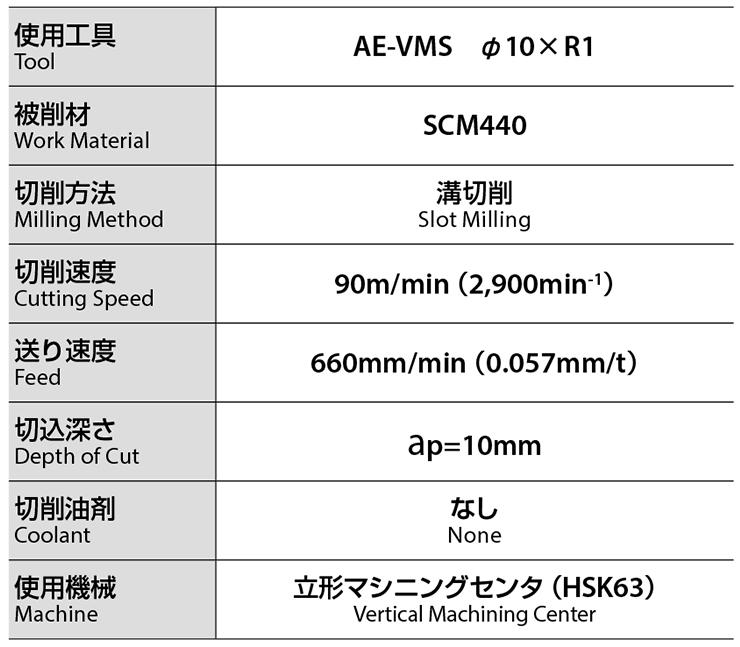

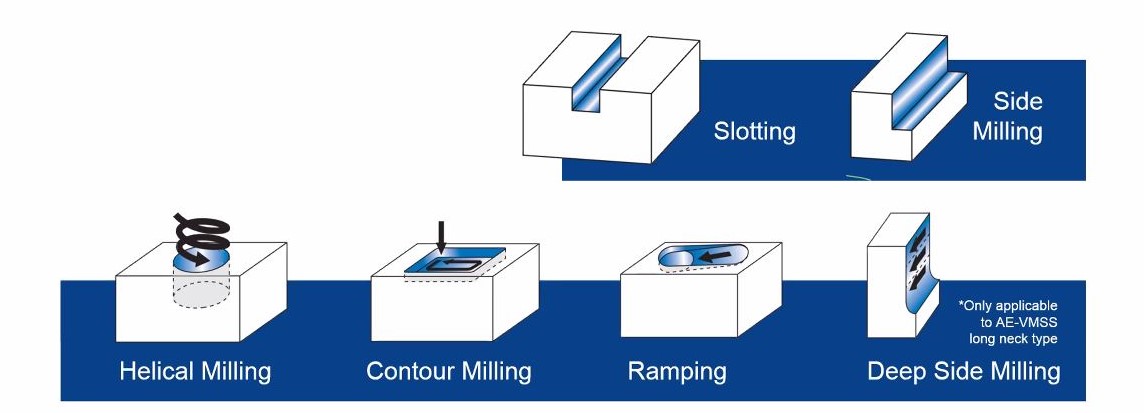

AE-VMS is designed for a wide range of milling applications.

- Provides a better surface finish with minimal vibration and burr formation.

- Works well on stainless steel, cast iron, carbon steel, alloy steel and hardened steel (up to 40 HRC). Radial (R) AE-VMS works up to 45 HRC.

- Unequal tooth spacing and groove geometry variations provide stable and efficient milling, reducing noise generation.

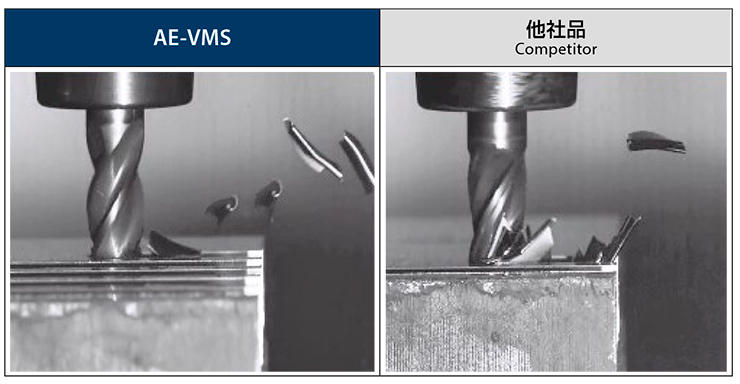

- Excellent chip evacuation even in slotting, resulting in performance consistent with the targeted tool life.

- Prevents heat generation from continuous use, resulting in stable surface finish, less tool wear and longer tool life.

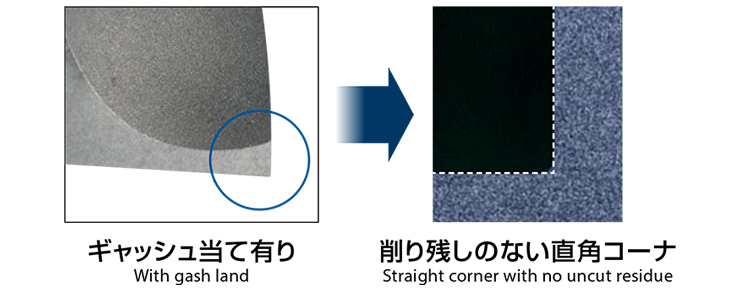

Right angle type : for milling straight corners with no uncut residue

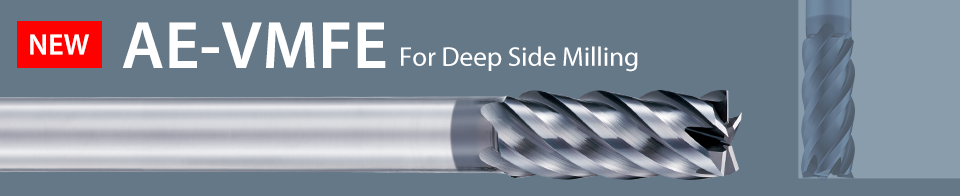

AE-VM Series carbide end mills are vibration-proof. There is also an AE-VMFE model for deep milling. See more details here.