The numerous merits of BIG-PLUS

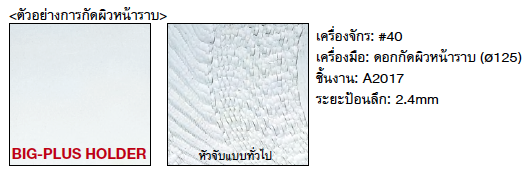

- Improved surface finish & dimensional accuracy

- Extended tool life

- Prevention of fretting corrosion caused by heavy cutting

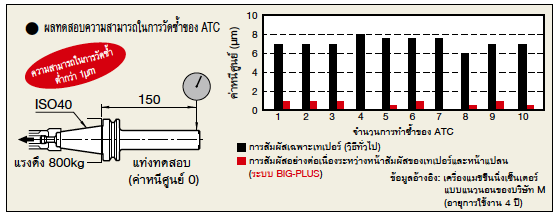

- ATC Improvement of ATC repeatability

- Elimination of Z-axial movement at high speeds

- Improved roundness of boring operations

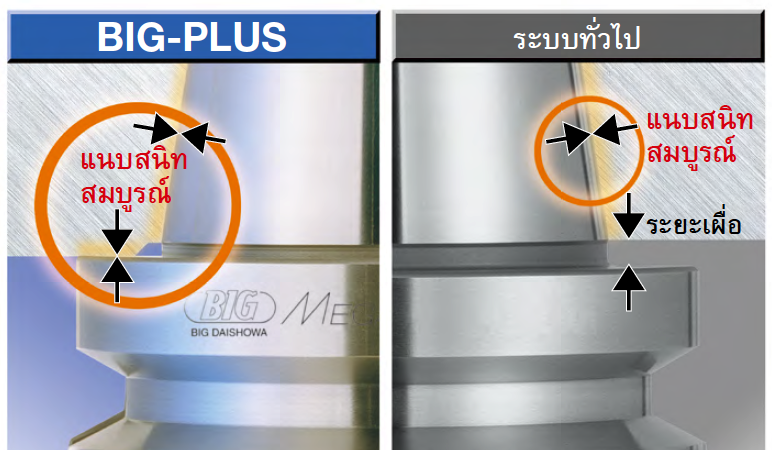

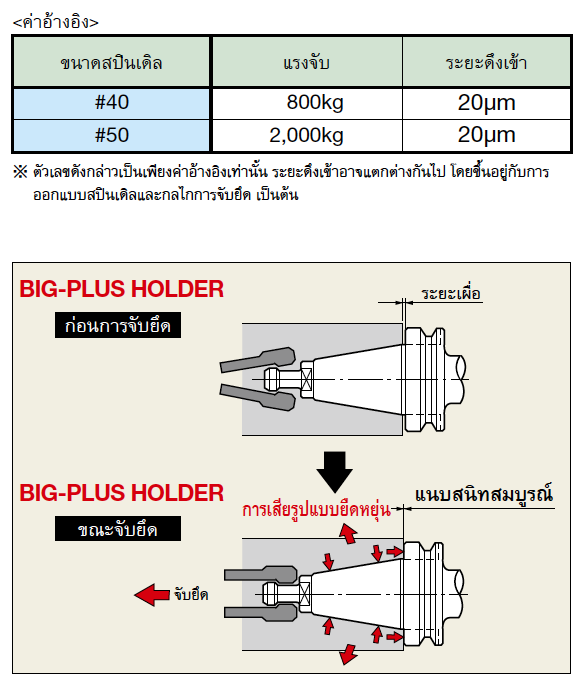

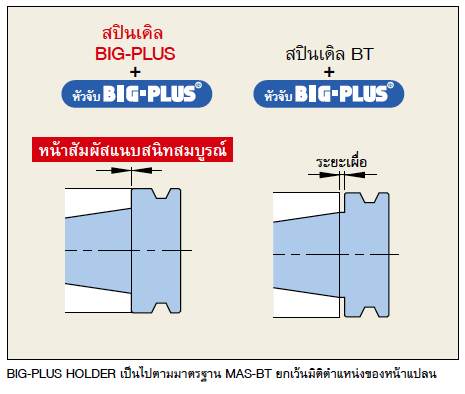

The chuck’s pull-in distance is key to perfect contact!

- before clamping with the chuck There will be a slight tolerance at the flange contact surface. The tensile force from the pulling equipment causes the spindle taper to widen. Make the contact surface completely close. Therefore, the pull-in distance is important for complete attachment.

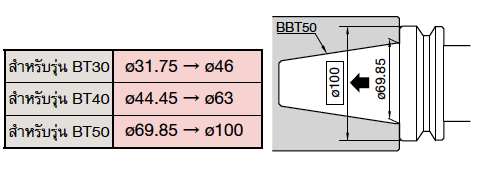

Increased contact diameter Makes the stiffness higher

- A typical BT tool holder sits on a reference diameter called a gauge contact. But on the other hand The BIG-PLUS tool holder sits on a flange, which significantly improves stiffness

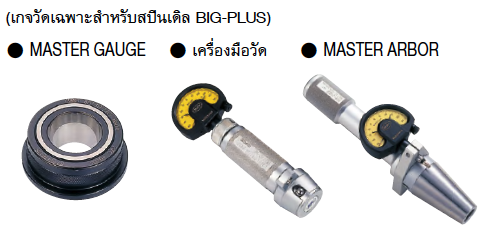

Strict Gage Control

- BIG-PLUS spindles produced by the licensed machine or spindle builders are strictly controlled in dimensions by the BIG original Master Gage. Only the BIG-PLUS trademarked tool holders can achieve the optimal performance fully and safely.

The 7/24 taper double-sided contact system offers easy operation and excellent results.

The ultimate combination of “BIG-PLUS spindle” and “BIG-PLUS HOLDER”

- The BIG-PLUS Spindle system maximizes the efficiency of the double-sided contact by combining the BIG-PLUS HOLDER and the BIG-PLUS spindle. The BIG-PLUS HOLDER can also be used with the spindle. can be used with a standard BT spindle. However, use with a standard spindle will not result in double-sided contact. Therefore, for superior double-sided contact performance Therefore, BIG-PLUS HOLDER should be used together with BIG-PLUS spindle. Please be careful not to use any type of double-sided contact chuck other than BIG-PLUS HOLDER as this may cause damage to the spindle. BIG-PLUS can

- BIG-PLUS HOLDER is recommended for spindles. BIG-PLUS Avoid using BIG-PLUS HOLDER with the BT chuck in the BIG-PLUS spindle.

Improvement of ATC Repeatability

- The BIG-PLUS Spindle System assures the highest precision location of the tool holder in the spindle when using the ATC for loading tools as a result of the dual contact, which precisely positions the tool holder within 1 micron.

Recommendations

- BIG-PLUS spindles are widely used worldwide by machine manufacturers or authorized spindle manufacturers. Under strict dimensional control with MASTER GAUGE to protect the spindle or prevent accidents that may occur with the spindle. Please use only tool holders with the BIG-PLUS trademark.