DLC Coated Carbide End Mill for Non-Ferrous Materials – High Performance Type

- Its DLC-IGUSS coating further improves tool life with excellent welding resistance and lubricity, which is effective in the machining of non-ferrous materials such as aluminum alloys.

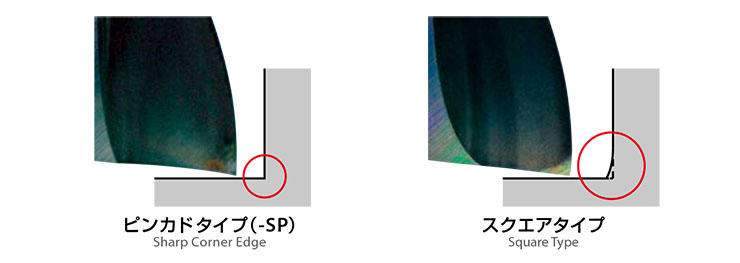

- In addition to square and radius styles, sharp corner edge type has been newly added to the lineup to enable effective corner milling with no uncut residue, which can be used in a wide range of applications.

- Manufacturer’s technology that can be quickly and better developed under the concept: The A Brand, convenient and easy to choose and use.

Features

- DLC-IGUSS coating

- Flat cutting edge specification achieves higher precision machined surface quality

- The three cutting edges are connected at the center to equalize cutting load, which enables greater stability at high speed milling

- Center cutting edge specification to enable plunging

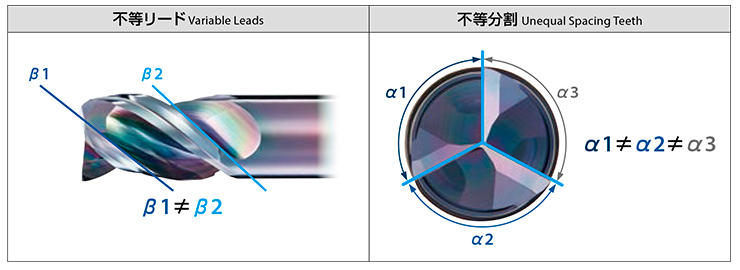

- Variable-lead geometry suppresses vibration

Variable-lead geometry suppresses vibration

- Standard type (AE-TS-N・AE-TL-N) DLC coated carbide end mill for non-ferrous materials is also available.