Features

- ABSOTECH™ PVD Coating Technology – Superior wear resistance and extended tool life

- Newly Developed Carbide Substrate – Enhanced strength, reduced risk of chipping

- Designed for Exotic Materials – Ideal for Inconel, Hastelloy, Titanium Alloys

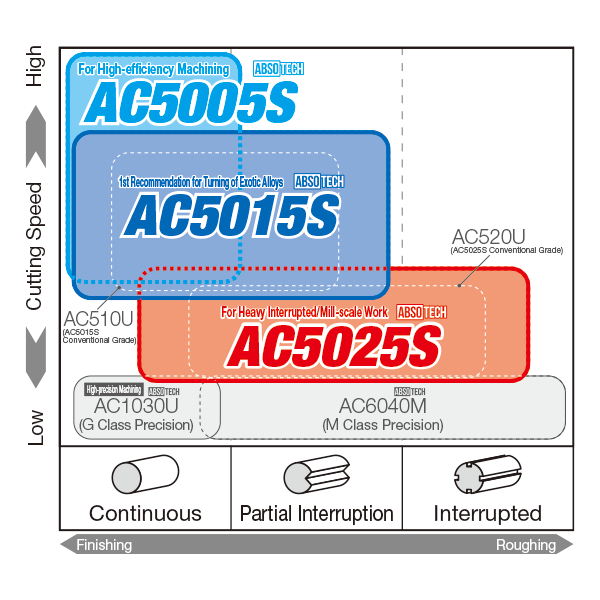

- Suitable for All Cutting Applications – From Fine Finishing to Heavy Roughing

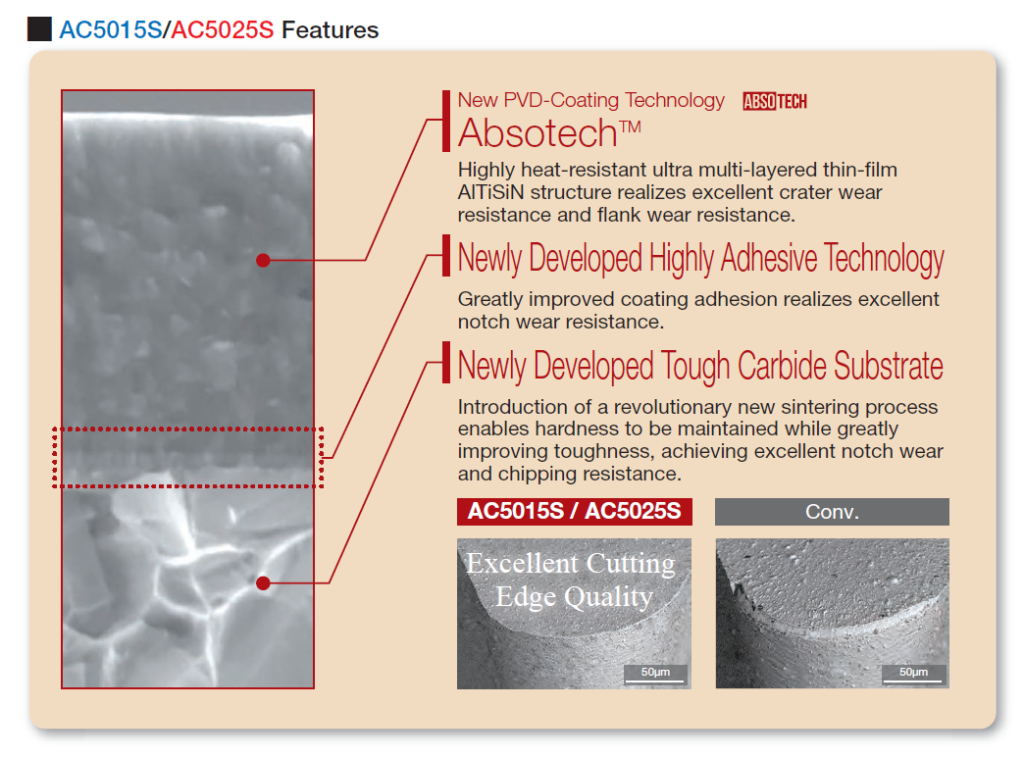

New PVD-Coating Technology AbsotechTM

- Highly heat-resistant ultra-multi-layer thin-film AlTiSiN structure realizes excellent crater wear resistance and flank wear resistance.

Newly Developed Highly Adhesive Technology

- Greatly improved film coating adhesion realizes excellent boundary defect resistance.

Newly Developed Rigid Carbide Parent Material

- Introduction of a revolutionary new sintering process enables hardness to be maintained while greatly improving rigidity, realizing reduces boundary defects and chipping resistant performance