Manufacturer’s technology that can be quickly and better developed under the concept: The A Brand, convenient and easy to choose and use.

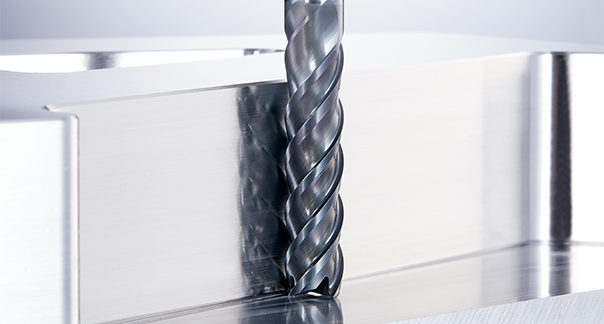

- The AE-VM anti-vibration carbide end mill series is ideal for a wide range of materials ranging from carbon steel, alloy steel and stainless steel to titanium alloys and Ni-based alloys.

Features

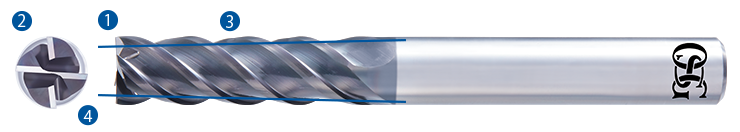

1. “DUARISE coating” provides excellent lubricity, superior friction-resistance and high oxidation temperature

2. Sharp positive rake angle reduces cutting force

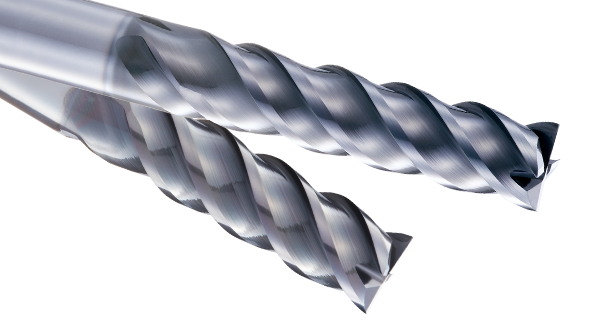

3. The web taper geometry, where the thickness of core changes from the cutting edge to the shank, greatly improves tool rigidity, thereby prevents the machining surface from tilting

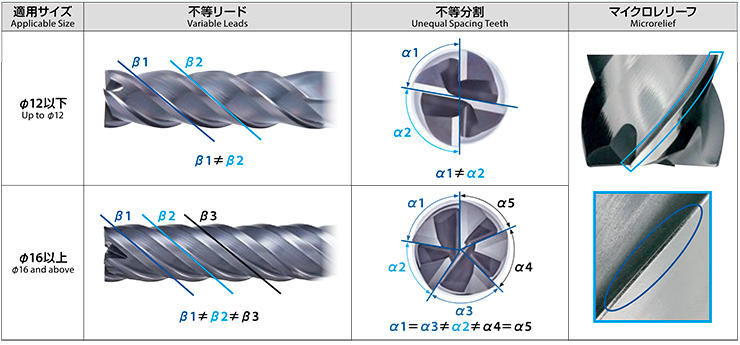

4. High anti-vibration effect by the combination of variable lead, unequal spacing teeth and microrelief geometry