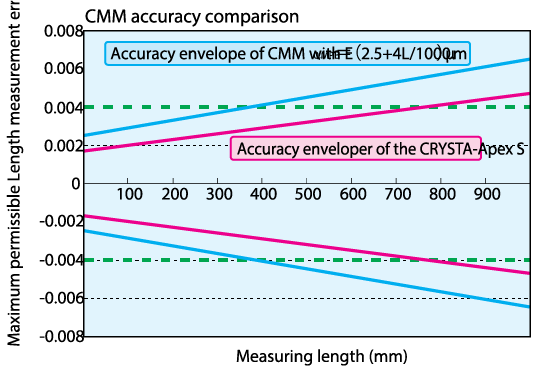

High accuracy in the 1.7μm class

- The CRYSTA-Apex S is a high-accuracy CNC coordinate measuring machine that guarantees a maximum permissible error of *E0,MPE = (1.7+3L/1000)μm [500/700/900 Series]. Comparing the CRYSTA-Apex S with CMMs offering *E0,MPE of approximately (2.5+4L/1000)µm where a required tolerance on a dimension is ±0.02 mm, then the measuring machine uncertainty should be no more than one-fifth (ideally one-tenth) of that, i.e. 4μm. This means that with a general-purpose CMM, when the measured length exceeds 14.8”(375mm), machine uncertainty exceeds one-fifth of the dimension tolerance in this case. In contrast, as shown in the figure on the right, with the CRYSTA-Apex S the measurement uncertainty remains within one-fifth of the dimension tolerance up to 30.2” (766mm). The higher accuracy specification of the CRYSTA-Apex S therefore gives it more than double the effective measuring range in terms of accuracy-guarantee capability in this case.

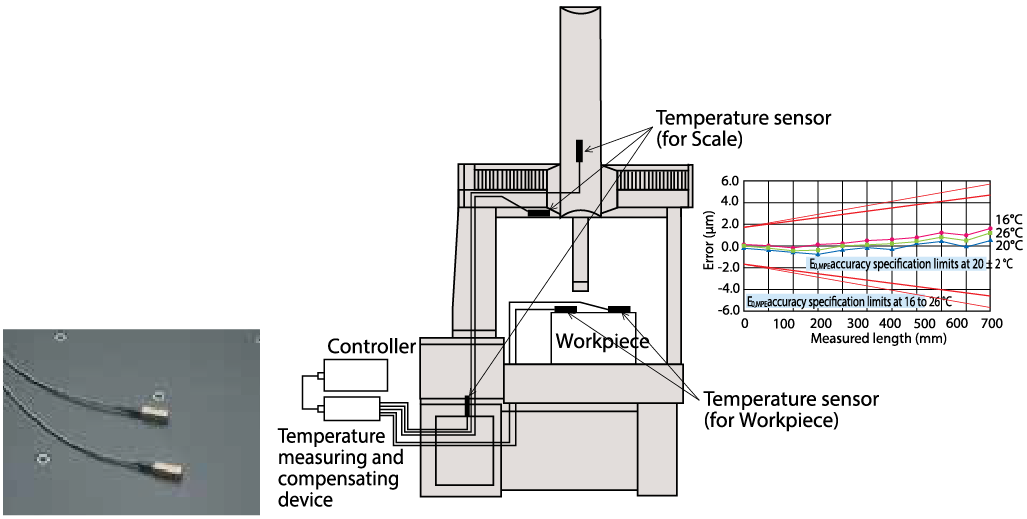

Temperature compensation system

- CRYSTA-Apex S is equipped with a temperature compensation system that guarantees measurement accuracy under temperature conditions of 16 to 26°C. Each scale is equipped with a temperature sensor. It works with sensors placed on the workpiece. It detects the temperature of the scale and workpiece. By detecting the temperature, adjusting the measurement results to a value that should be measured at 20°C and then calculating the coefficient of expansion of the workpiece. before sending the obtained values to the controller, as well as the characteristics of the general 3-meter measuring device.

- The combined temperature/scale/workpiece temperature compensation method used in CRYSTA-Apex S provides significantly better results compared to systems that compensate only for scale temperature.

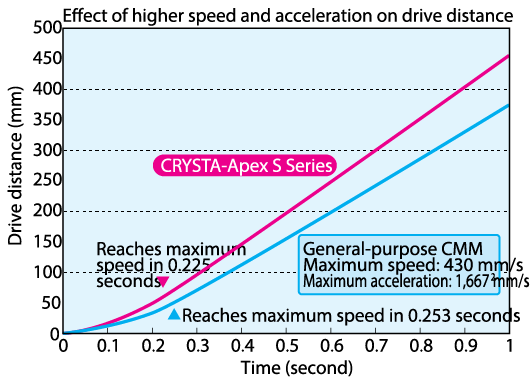

Driven by high speed and acceleration

- The CRYSTA-Apex S Series has a maximum driving speed of 519 mm/s and a maximum acceleration of 2,309 mm/s2 [500/700/900 Series], allowing it to travel nearly 100 mm more per second when compared to a universal CNC 3D measuring machine (maximum speed of 430 mm/s and maximum acceleration of 1,667 mm/s2). In addition, the maximum measurement speed (i.e. the speed at which the stylus moves on the workpiece ) at 8 mm/s, the CRYSTA-Apex S measures faster than conventional 3D measuring machines (maximum measurement speed is 5 mm/s). With higher speed and acceleration, the CRYSTA-Apex S can reduce the time very measurable The difference between the CRYSTA-Apex S and conventional 3D measuring machines is not just the additional measurement points. And it can also clearly reduce the cost of measurement.

Designed for high strength

- Various structural variations are used in the CRYSTA-Apex S to increase the strength of the unit. Like Mitutoyo’s other 3D measuring devices, In particular, the Y-axis structure attached to one side of the granite sheet shows little wear and tear from use. This ensures that the machine will maintain high precision for a long time. In addition, air bearings located on the bottom, front, rear and top surfaces of the X-axis rail body reduce vibration even during high speed and acceleration movements. Helps make linear movement more stable.