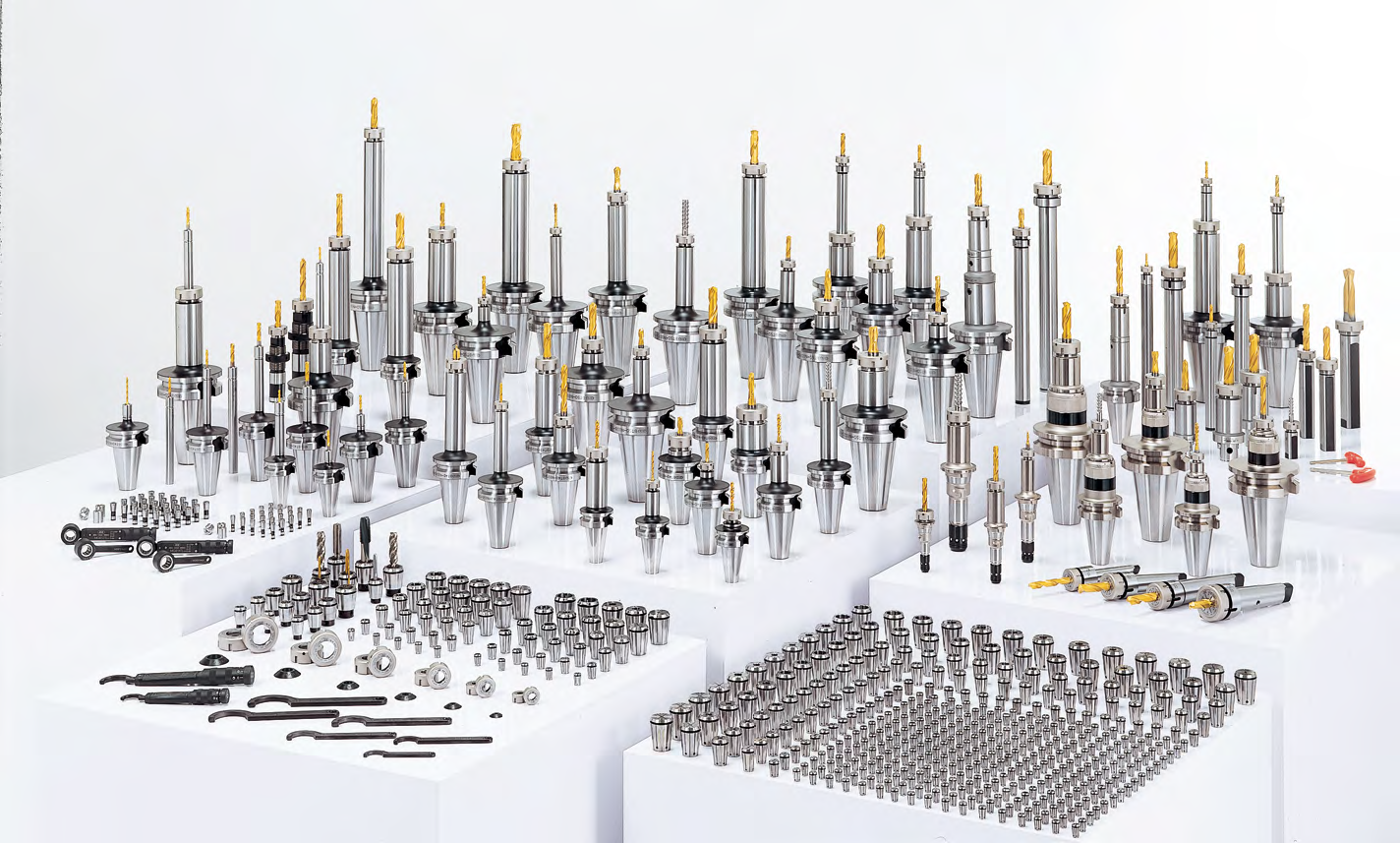

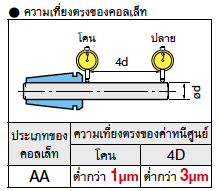

High-precision collet equal to the sub-micron level (Mounting diameter ∅0.25 – ∅20)

The New Baby Chuck collet uses knowledge cultivated through years of experience to produce the world’s highest precision collet program.

The New Baby Chuck collet uses knowledge cultivated through years of experience to produce the world’s highest precision collet program.

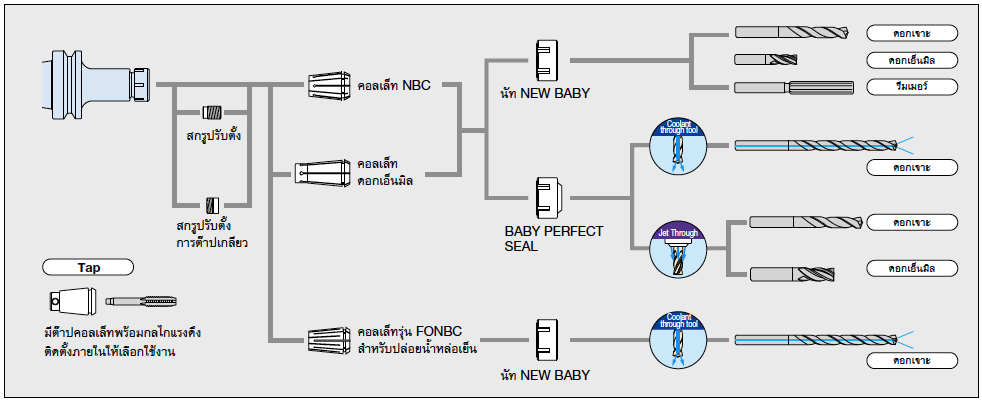

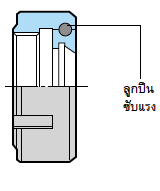

New Baby Nut ensures high accuracy

The double effect of precision threads finished after heat treatment and the smooth tightening of the thrust balls without torsion on the collet achieves stable high-precision collet tightening. Furthermore, the mechanism acts to prevent the thrust ball from jumping out due to centrifugal force generated by high speed rotation, promising stable machining.

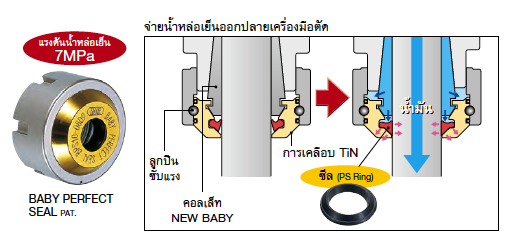

Coolant method to suit the application

The sealing pattern of PERFECT SEAL is that the higher the coolant pressure, the closer the PS Ring will be to the tool holder. As a result of the hermetic sealing system, even high-pressure cutting can completely release water from the tool tip. It is a sealed nut cover that can be used with standard collets.

A coolant nut with oil sealing functionality.Removing the internal PS Ring allows jet-through coolant supply.

A coolant nut with oil sealing functionality.Removing the internal PS Ring allows jet-through coolant supply.

Recommendation: Run-out at the tip of the cutting edge has a significant impact on the cutting performance and life of the cutting tool. It is recommended to use a suitable collet such as the E series collet for holding end mills. Use a collet with a 0.1mm step collapse if high precision is