This Micrometer enables 0.1 μm resolution measurements and is ideal for customers who need to make highly accurate measurements with a hand-held tool (such as Gauge R & R analysis). The Absolute High-Accuracy Micrometer offers the following benefits:

- It delivers higher accuracy without sacrificing operability, by using Mitutoyo‘s innovative 0.1 μm resolution ABS (absolute) rotary sensor and high accuracy screw machining technology which reduces instrumental error to just 0.5 μm.

- Its highly rigid frame and high-performance constant-force mechanism (7-9 N) enable more stable measurement.

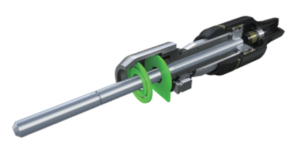

Ratchet Thimble with an anti-friction bearing

ABS (absolute) rotary encoder with a resolution of 0.1 and high-accuracy thread cutting technology

Heat transfer reduction with a heat shield

Example of measurement

Functions

- Preset (ABS measurement system): The measurement origin can be preset to any value within the display range for convenience in measuring

- Zero-setting (INC measurement system): The display can be zeroed at any position of the spindle, making comparison measurement easier. Returning to the absolute-measurement mode is easily accomplished.

- Hold: The displayed value is held while the spindle is withdrawn and the micrometer moved so that the display can be read at the operator’s convenience. After cancelling the hold, the instrument returns to the previous measuring mode (absolute or incremental).

- Resolution switching: The resolution of the display can be switched. If 0.1 μm measurement is not required, the resolution can be switched to 0.5 μm.

- Function lock: Functions such as preset or zero-set can be locked to avoid inadvertently changing the origin position.

- On/off: The power can be turned off after measurement is complete. Even after the power is turned off, the origin or last zero-set position remains in the memory.

- Auto power off: Even if the power is left on, the power turns off automatically if the micrometer is not used within a 20-minute period.

- Measurement data output: Measurement data can be output, allowing easy incorporation of this instrument into a statistical process control or measurement system.

- Error alarm: In the unlikely event of a display overflow or calculation error, an error message is displayed and measurement stops. Measurement cannot continue until the error is corrected.

- Also, if the battery voltage drops below a certain point, the battery indicator will turn on before measurement becomes impossible, warning the user that the battery needs to be replaced.