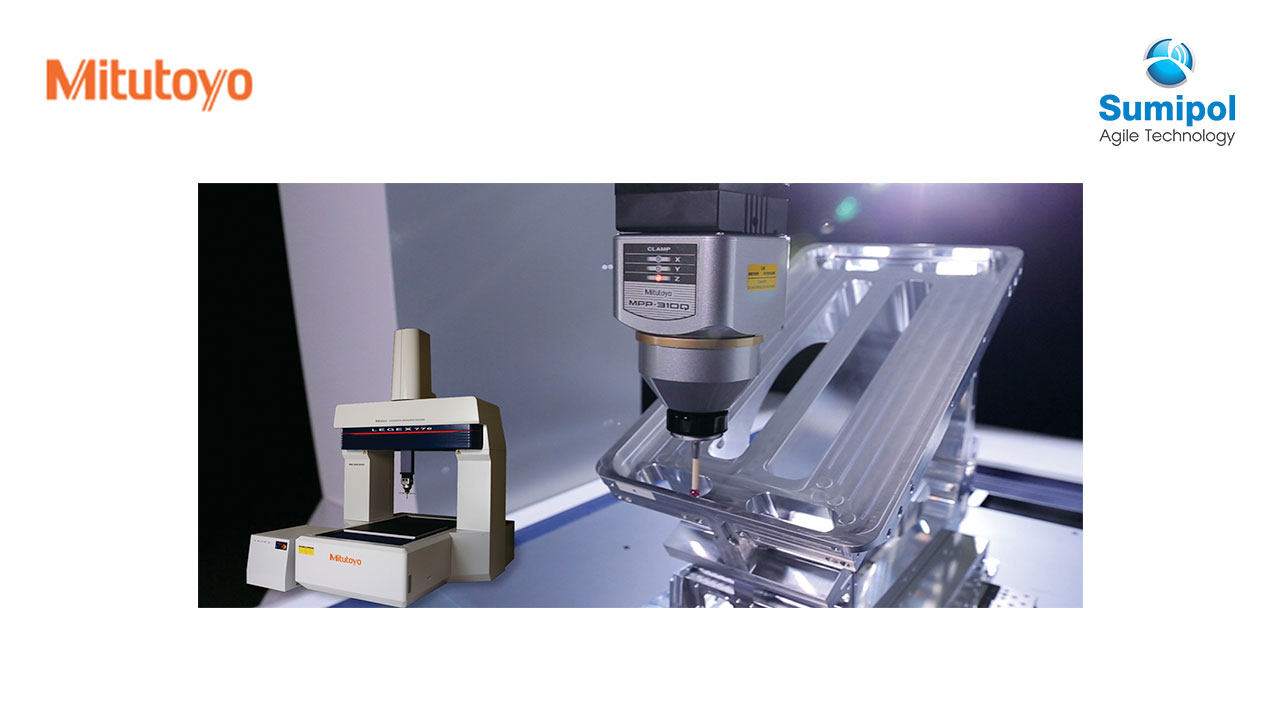

Achieving premium performance, the LEGEX series with its fixed bridge structure and precision air bearings resting on the rigid guide ways ensures superior stability of motion and ultra-high measuring accuracy. Thorough testing, using FEM structure analysis simulation, guarantees geometric motion accuracy that has minimal errors from fluctuations in the load and other variables. The LEGEX series CNC CMM is suitable for complex small to medium size workpieces such as a gears, bearings, lens, precision dies, or other high precision workpiece that requires dimensional accuracies with small tolerances.

The LEGEX series CNC CMM is ideal for small to medium sized complex workpieces such as gears, bearings, lenses, precision molds or other high precision workpieces that require dimensional accuracy with small tolerances.

The LEGEX series consists of an ultra-high precision weighing unit with crystallized glass scales (thermal expansion coefficient of 0.01×10-6/K) and a high-resolution, high-performance reflective linear encoder that provides premium positioning performance. All LEGEX high-precision series CMMs are temperature compensated, so no temperature-controlled chamber is required. Accuracy is guaranteed in the range of 18 to 22°C.

MPP-310Q Mitutoyo’s MPP-310Q probe can be used for point-to-point measuring and continuous scanning applications. If the workpiece requires the maximum accuracy, the MPP-310Q can offer ‘zero-point’ data acquisition for statistical measurement. In this mode the MPP-310Q obtains the measurement data after all the CMM slides have come to a complete standstill. This statistical measurement is intended to eliminate dynamic effects on measurement