Huge versatility across a wide envelope

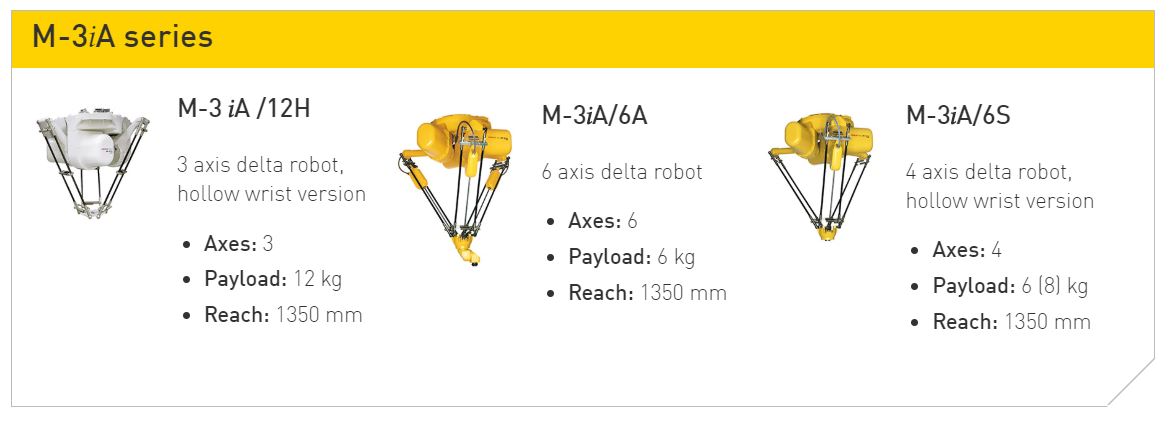

Specifically designed to maximise speed and versatility on high-speed small part handling and picking operations across a range of industries including food, pharmaceutical and electronics, M-3 robots are available with either 3, 4 or 6 axes. Their unique parallel-link structure and very large work envelope makes them ideal candidates for automating demanding applications that traditional serial-link or scara robots are unable to perform.

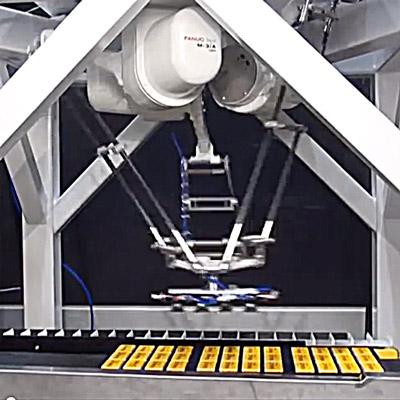

Higher acceleration for smaller footprintPurpose built for high-speed and rapid acceleration, the extraordinary levels of performance offered by M-3 series robots keeps the number of robots required on a line to a minimum and helps condense your manufacturing footprint.

Highlights of M-3 delta robots

3 axis design for side-part feeding

Equipped with 3 axes at the wrist, the delta robot enables part feeding from the sides of a work zone, increasing the usable workspace.

Secondary food package available

Exceptionally smooth easy-to-clean surfaces, food-grade lubrication and white epoxy coating.

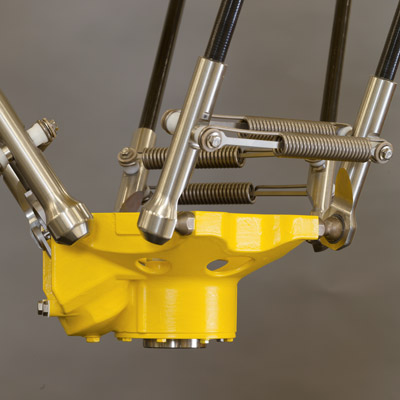

Multiple part picking and handling

The M-3’s payload enables the use of a bigger gripper for multi picking or handling larger individual items.

iRPickTool for multi-robot control

Line tracking and iRVision enable additional robot configurations for high-speed robot interaction on production lines and multi-robot setups.

IP67 protection

Standard IP67 protection makes the M-3 series ideal for environments with exacting hygiene standards.

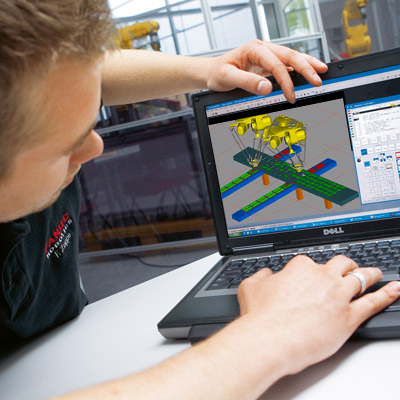

Get an insight into your application

By simulating your production scenario, Roboguide shows you exactly what the M-3 can do for you and where the savings lie.