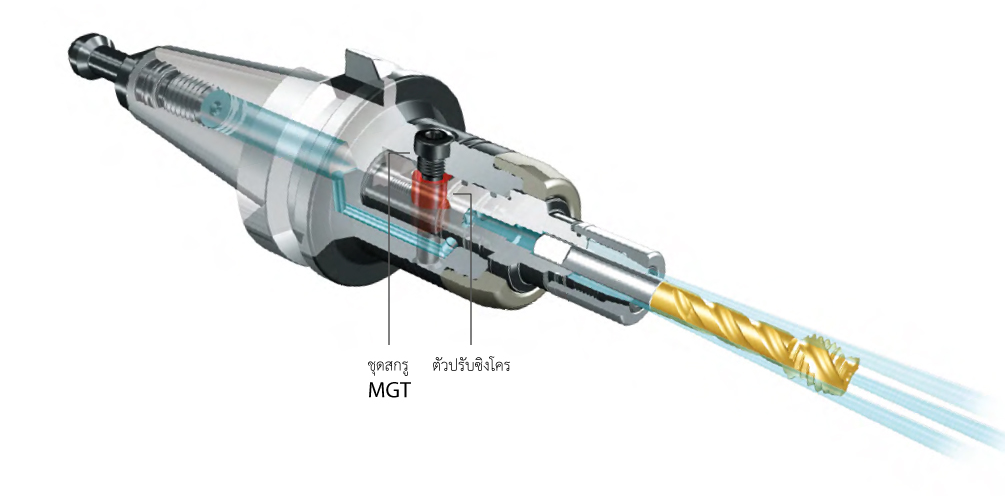

Cannot be used with machines without a synchronized tapping function

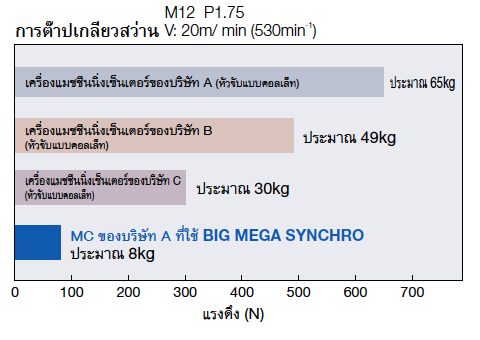

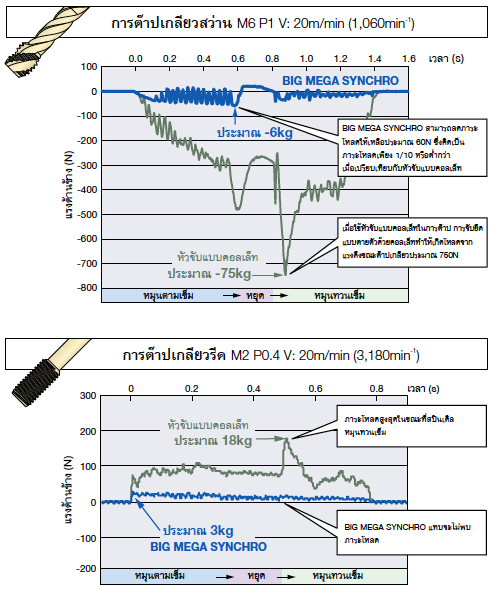

- Improves thread quality and tap life by reducing thrust loads caused by synchronization errors up to 90%

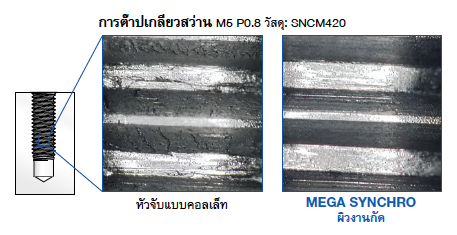

Compare tap surface

- Tapping materials that are difficult to cut with a collet chuck often results in compression marks on the thread surface. MEGA SYNCHRO compensates for synchronization errors and reduces the load on the thread. cut lower So you get a beautiful milling surface.

Reduces lateral force generated by both thread tapping and workpiece.

- This is due to the deviation of the feed distance that occurs when changing the direction of rotation from clockwise to counterclockwise. or tolerances that occur with the pitch of the thread itself. Therefore, 100% synchronization is often not achieved. MEGA SYNCHRO reduces lateral forces generated on both the thread and the workpiece to improve thread quality and tap life.

Tips: There are many cases where threading is the final step in machining a workpiece. Therefore, it is necessary to select the appropriate thread tap for safe threading for synchronous thread taps. as well Please be careful. This is because thread taps often break and are damaged. Or there are often burrs pressed on the surface.

Various thread diameter series From small to large