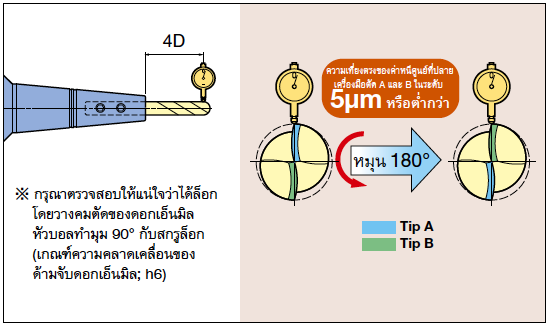

Runout accuracy within 5μm

- 2-flute ball endmills achieve a runout accuracy within 5μm. Both easy handling of side lock holder and high accuracy are realized.

Slim and tapered design minimizes interference

- The outer body has been finely milled. Can be used stably and accurately even for high-speed milling.

Slim and tapered design Helps reduce collision problems

- Helps reduce the problem of hitting obstacles in mold production. It is also useful in milling the angle of mold removal.

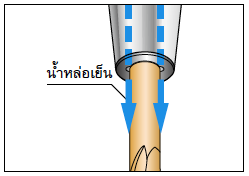

Distributes coolant to the cutting edge evenly with Jet through.

Because the coolant can be supplied through Central hole or atomization through the coolant channel. There are two channels, so it can distribute coolant to The tip of the tool cuts precisely, which is Very useful for milling difficult-to-cut materials.

Recommendations:

while biting the mold Depending on the workpiece geometry, there is difficulty in supplying coolant from outside to the cutting tool tip. With the properties of MOLD CHUCK, it can precisely distribute coolant to the tip of the cutting tool. And coolant can be supplied to the cutting tool tip at high pressure without the need for coolant holes.