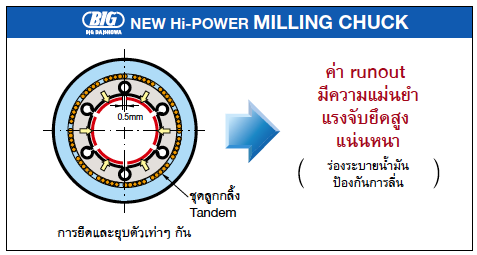

Reliable slit design ensures high accuracy

- A unique BIG slit shape is adopted to achieve both the essential runout accuracy and gripping force which are the key elements of a milling chuck. Stable clamping is possible due to sufficient elastic deformation and the ability to remove oil film from the tool shank.

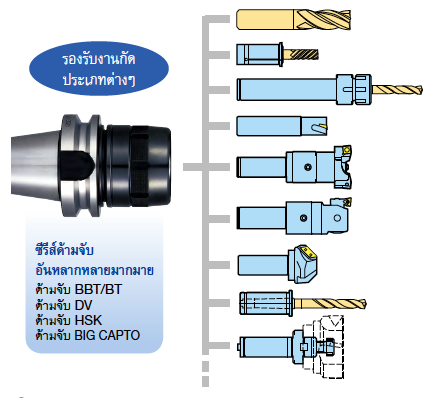

The Milling Chuck is also ideal as a basic holder

- Allows the reliable use of straight collets as well as boring bars, arbors such as face milling cutters. Also optimal as a basic holder.

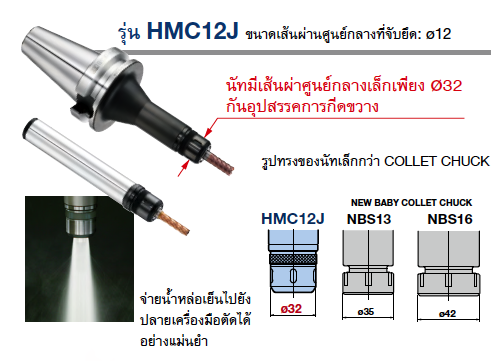

The RA chuck has adjustable run-out setting.

construction makes setting the accuracy of the run-out easier!

- The pilot hole diameter remains constant.

- Improve surface roughness

- The longevity of tool usage has increased.

Run-out value at cutting tool tip 2 µm or less

Compensates for the run-out of machine spindles that deteriorate due to continuous use for a long time. The simple construction allows for easy adjustment even on machines.

TIP : Since the MILLING CHUCK is a basic chuck that can be used with a variety of cylindrical shanks, it is not an exaggeration to say that It is the only choice that can determine the performance of the machine tool. Can be used in a wide range of applications from heavy milling to fine milling with superior clamping conditions. collapsible properties, precision, rigidity and durability.น