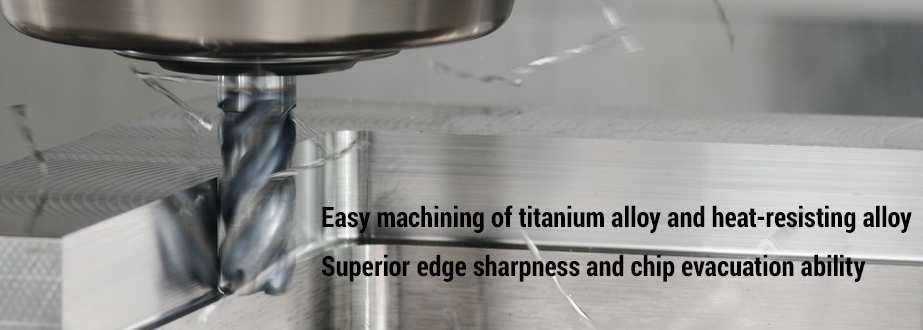

Uses strong helical corners to provide better cutting edge sharpness with smooth and reliable chip removal.

- Sharp cutting edges and superior chip removal ability

Uses a strong helix angle (45° thread) to provide better cutting edge sharpness with smooth and reliable chip removal. - The tool has high strength.

Adjust the thickness of the core The shape of the groove and the most appropriate size To achieve both tool strength and chip removal ability - Better resistance to sticking

The combination of a flute surface close to mirror polishing and a special coating layer improves wear and adhesion resistance. - Better resistance to chipping

The unique radius reduces cutting vibration and improves chipping resistance. - Special coating

Extremely smooth coating with greatly improved coating strength and heat resistance. Helps improve tool life for cutting heat-resistant metals.

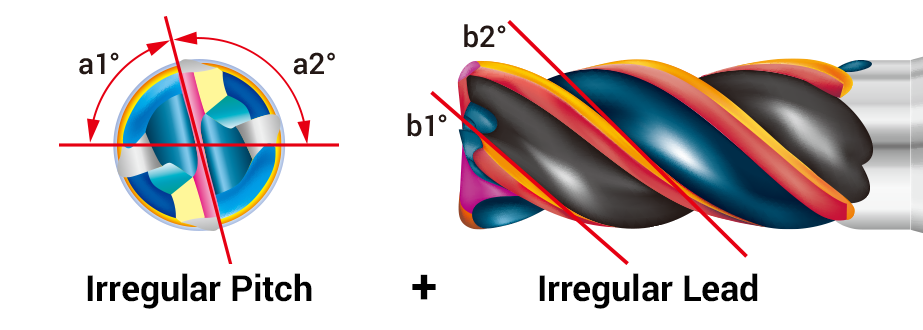

Anti-vibration type added to SSEH series end mills for special alloys.

Builds on the same features of the existing series by adding uneven conduction for excellent anti-vibration capabilities.

- For various special alloys including SUS, Inconel, Titanium, etc.

- Minimizes vibration to achieve high-speed cutting and high feed.

- Both coated and uncoated types are available in stock to meet a variety of needs.