GENERAL PURPOSE COATED CERMET FOR STEEL TURNING

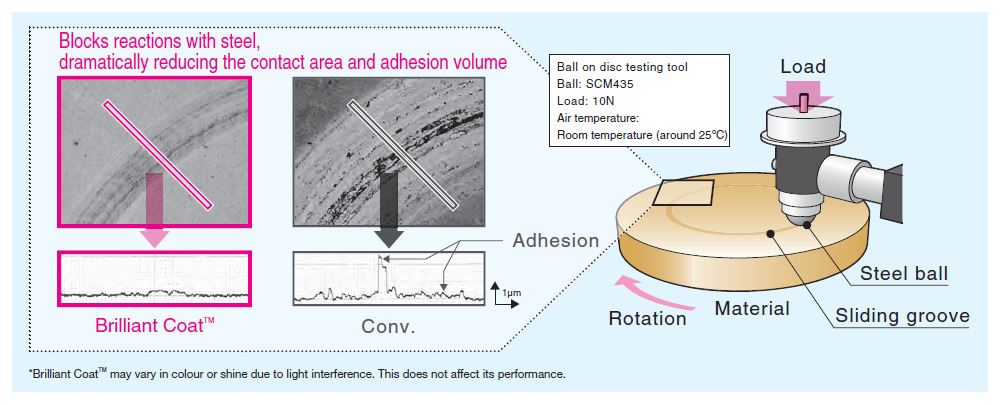

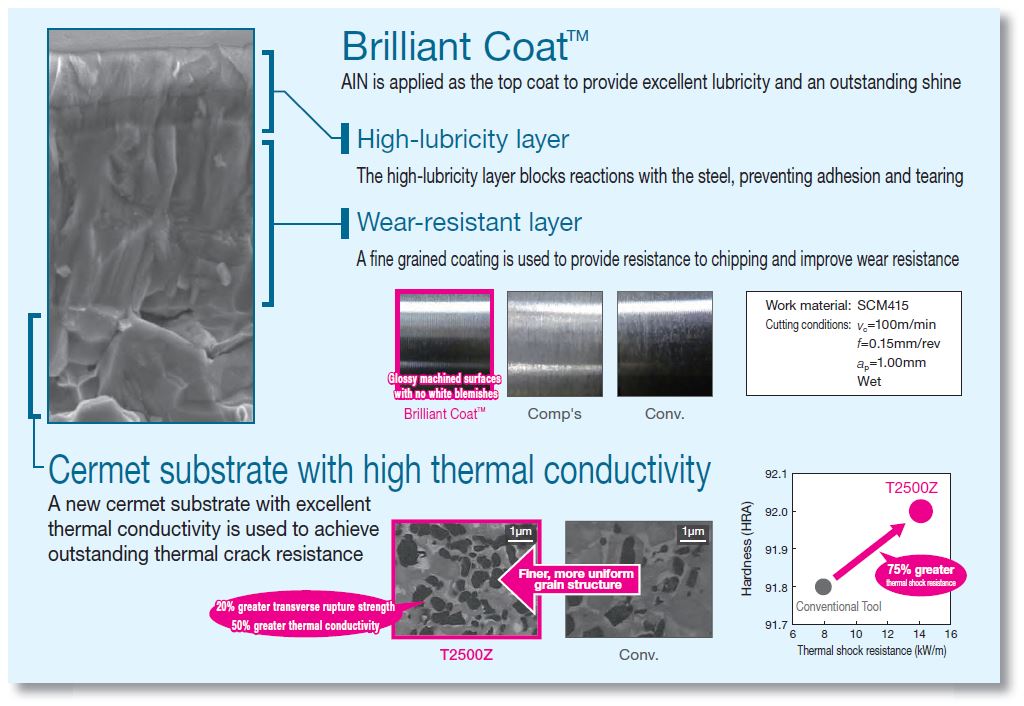

PVD coating process “Brilliant Coat” for glossy finished surface with excellent adhesion resistance. A general purpose coated cermet grade capable of maintaining high-quality finished surfaces while providing excellent wear resistance.

- PVD coating process, Brilliant Coat”

- Excellent wear resistance and fracture resistance

- Low reactivity with work materials for beautiful finished surfaces

T1500Z / T2500Z comes with the following outstanding features :

- PVD Brilliant Coat Process

Using AIN as top coat to achieve excellent chip evacuation and glossiness. - High-lubricity layer

The coating layer has high smoothness, low friction, does not react with steel, prevents piling and cracking. - Wear-resistant layer

The coating structure has finer grains than general inserts, to resist cracking and increase wear resistance. - CERMET surface with high thermal conductivity

With excellent thermal conductivity, it is used to achieve thermal cracking resistance.

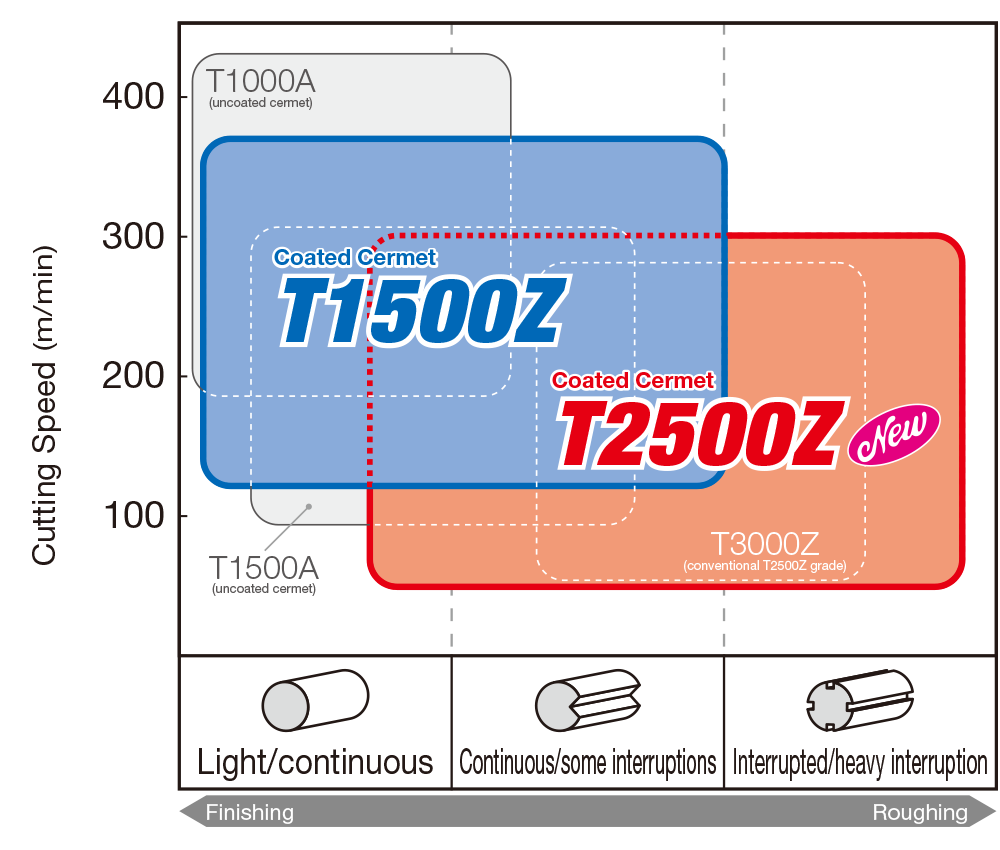

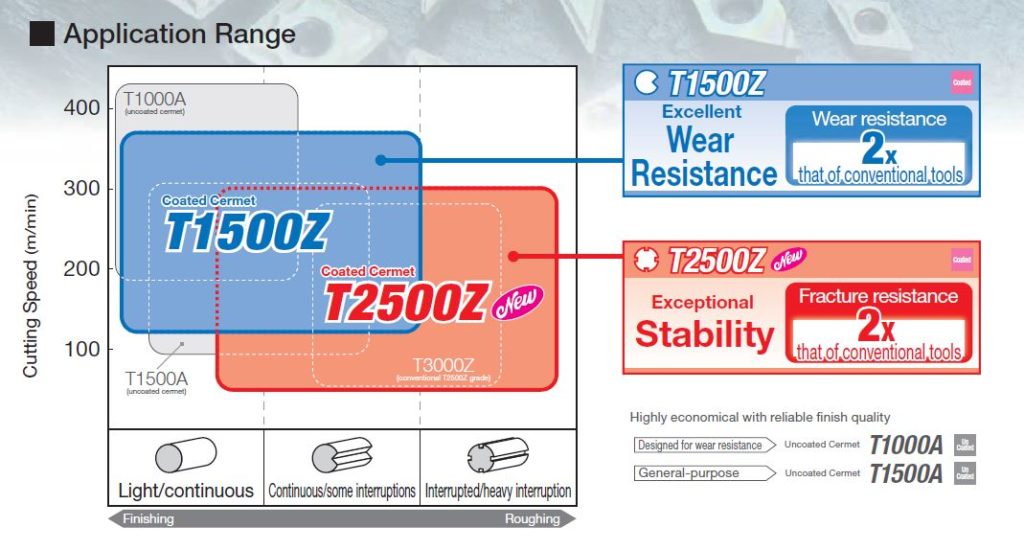

T1500Z – Suitable for general use

- Superior machining quality with Brilliant Coat, a new PVD coating with excellent chip evacuation. Coated Cermet inserts for general machining can provide high quality surface finish while providing excellent wear resistance.

T2500Z – Suitable for surface finishing / drilling with impact / fine finishing / impact turning / heavy turning.

- Cermet inserts are coated with an extra strong and stable grade of Brilliant Coat. A new Cermet surface with excellent thermal conductivity is used to achieve thermal cracking resistance.