Thread mill with end-cutting edge for high hardness steels

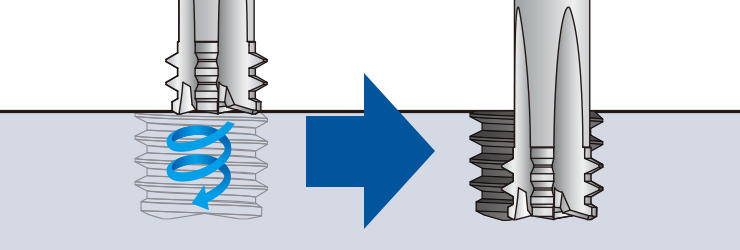

Helical drilling + threading can be done simultaneously.

- No pilot hole is required! Stable machining without chip trouble.

Newly developed DUROREY coating enables superior heat resistance and high toughness optimized for high-hardness steel milling!

1. Special cutting edge shape suppresses bending of the tool.

2. Left-hand cut configuration enables climb milling to prolong tool life.

3. Roughing teeth are added to distribute the load.

Use RPRG to reduce the workload

- RPRG is the reference value of tool radius offset. Conventionally, the tool radius value is entered during setup as a parameter of the NC system, which is corrected by checking the thread with a gauge. Now, the process of correction can be simplified by simply inputting the RPRG value as indicated on the tool shank.

Support

Three Support Tools for Your Thread Milling Needs

1. Reduce Setup Time

2. Reduce Machining Time

3. Achieve Stable Tool Life